Concept & objectives

A multidisciplinary approach to develop safe and long lifetime

The SPIDER project (H2020 Grant Agreement n° 814389) proposes a multidisciplinary approach to develop safe and long lifetime, high energy density cells. This approach is based on new materials, improved chemistries, new industrially relevant manufacturing process steps and complimented by in-depth characterization, safety, modelling and Life-cycle-(cost) analysis studies.

SPIDER technologies will be implemented on 4 successive advanced Li-ion cell generations in which the presented concepts will be successively introduced to get better understanding of Li-ion battery cost, performance, recyclability and safety to enable electric vehicles to rapidly gain market share and reduce CO2 emissions.

The project will bring innovations in 4 strategic domains:

High capacity materials :

LTS Cathode

- Optimization of the synthesis parameters to obtain a material with a capacity higher than 400 mAh/g

- Tuning the material composition to increase the average potential of the material

- Active materials will be optimized and processed at kg batch scale

High capacity materials :

Carbon composites anode

- Development and preparation Si-C composite-based anode materials with a target capacity of 1000 ‑ 1500 mAh/g

- Preparative work and development partly on large lab scale in order to investigate processing aspects as well, i.e. in the range of up to 3-5 kg

Prelithiation :

- Implementation of selected prelithiation process at cell level compatible with industrial requirements

Advanced electrolyte formulations :

- Development and optimization of safe electrolyte for HV LTS / Si – C composite chemistry

Project description

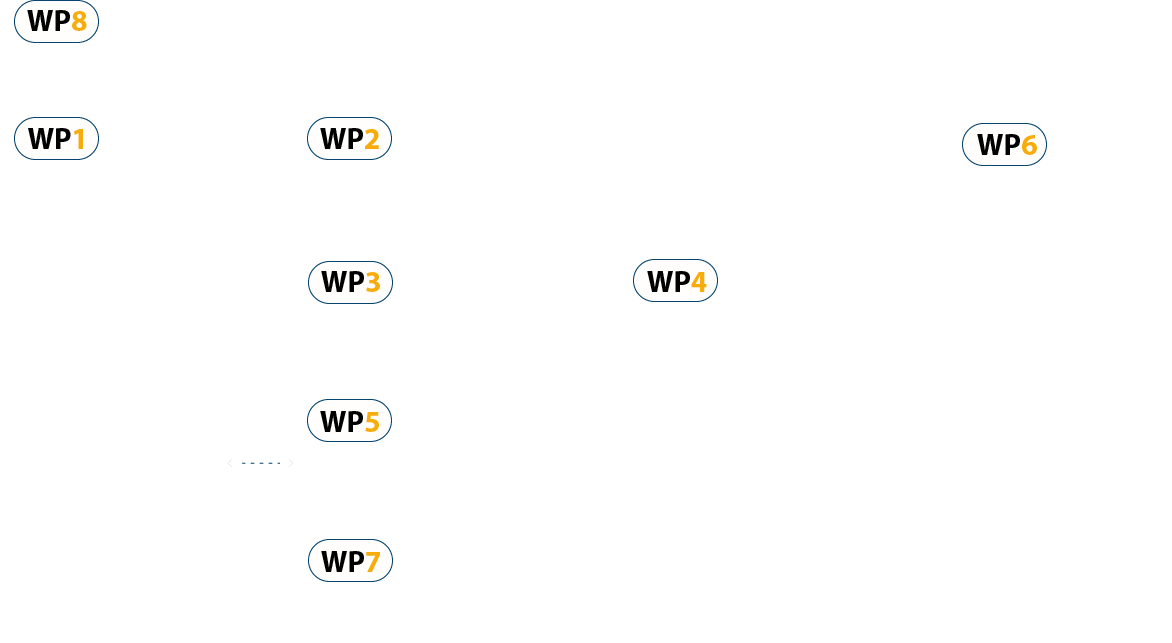

The project is organised in 8 workpackages, as illustrated in the simplified chart below

Expected results

The project aims at achieving the performances below

| Key Performance Indicator at cell level |

Baseline (NMC622/Graphite) |

SPIDER technology | |

|---|---|---|---|

| 2022 | 2030 | ||

| Energy density (Wh/kg) | 240 | 390 | 450 |

| Power density (Wh/kg) | 700 | 800 | 800 |

| Durability (number of cycles) | 500 – 100 | Up to 2000 | Up to 5000 |

| Cost (€/KWh) | 180 | 90 | 75 |

| Safety (Thermal energy dissipation (kW/kg) |

20 | 4 | 4 |

| Recyclability (recycling efficiency in %) | 50 | 60 | 60+ |

| Sustainability (dependence on Critical Raw Materials) | Cobalt, Nickel | Absence of Cobalt and Nickel |

Absence of Cobalt and Nickel |