Authors: Isidora Cekic-Laskovic (FZJ) and Elie Paillard (POLIMI)

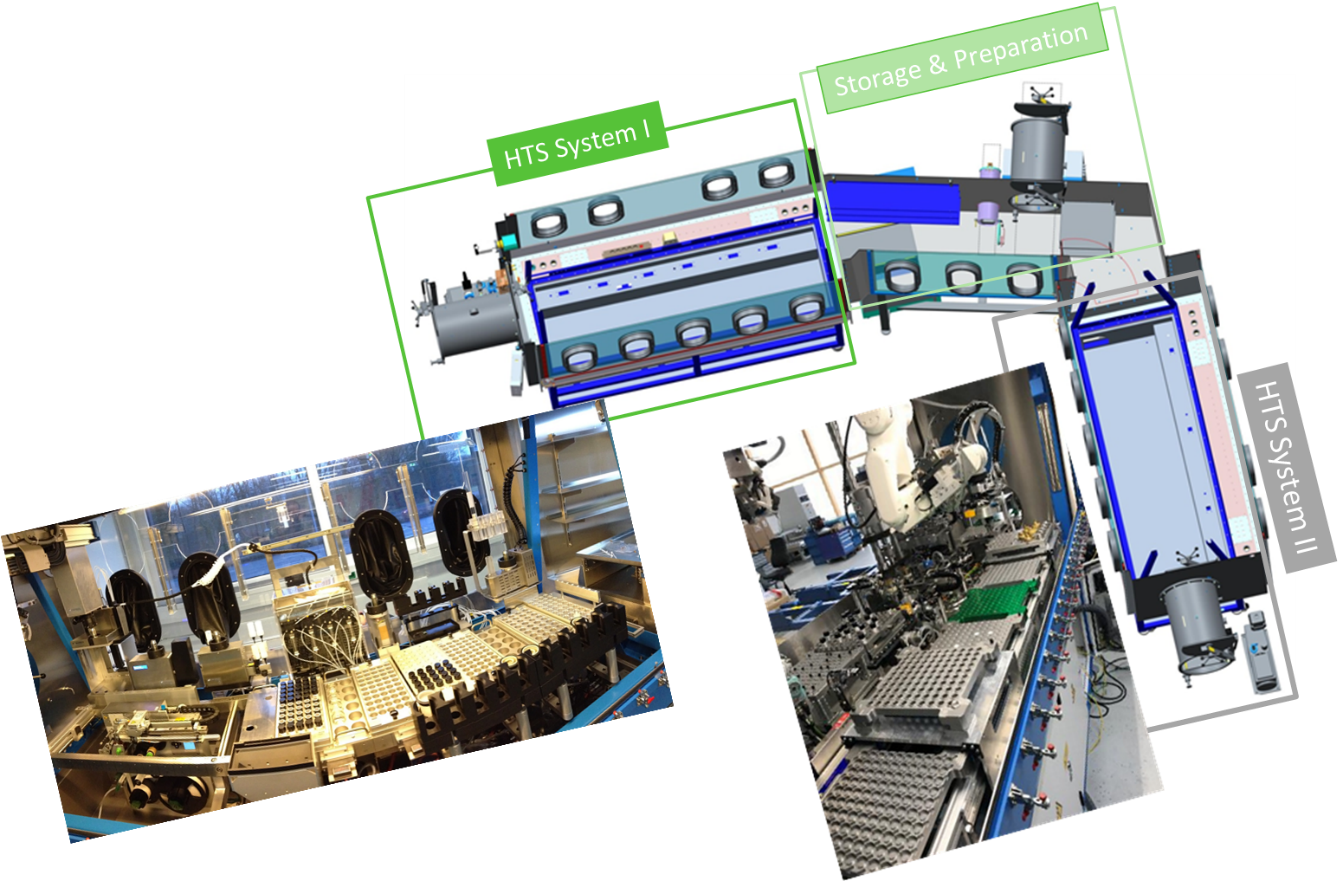

The development of novel nonaqueous aprotic electrolytes within the SPIDER project intends to enable long cycle life Si-Gr-based lithium ion battery cells with significantly advanced safety. For this reason, high throughput screening (HTS) equipment, available at Helmholtz Institute Münster/Forschungszentrum Jülich (FZJ), was employed to fully automatically formulate 50 electrolytes varying in composition (HTS System I, Figure 1) for each generation of prototype cells. Coin cells are then automatically assembled using electrodes developed in WP5 by a HTS System II (Figure 1), while online measurement allowed for determining water content in electrolyte formulations. All the information are stored in the laboratory information management system (LIMS) database and printed via 2 D data matrix code onto the electrolyte containing vials and coin cells.

Figure 1. Illustration of the high throughput screening system at FZJ

This approach allows identification of the most appropriate electrolyte combination possible for a given cell chemistry, using functional additives, co-solvents and conducting salts provided by SOLVAY. The lead electrolyte formulations are thereafter sent to CIDETEC to validate the results in cell prototypes and select the best functional additive. Centro Ricerche Fiat (CRF) contributes in analysing the gases produced at the electrodes via differential electrochemical mass spectrometry (DEMS) for gaining insights into the anodic and cathodic interfacial reactions.

The first generation of SPIDER prototype cells uses an electrolyte formulation optimized in terms of functional additives and derived from a state-of-the-art formulation developed with only cell electrochemical performance in mind that allowed a 20% increase in terms of cycle life. Besides, non-flammable and low flammability electrolyte lines are being developed at FZJ and Politecnico di Milano and are already included in the screening for GEN1 cells.